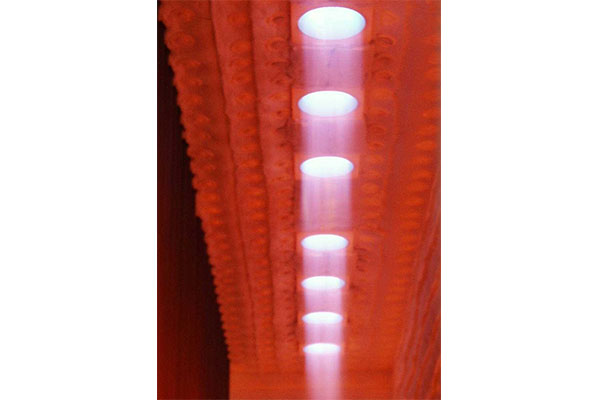

Proven in a wide range of petrochemical applications – such as hydrocarbon processing to steam reformers – Lanemark HC burners all gain from the unique Thermimax matrix burner head design.

Both forced and induced draught options are available while a choice of up firing, horizontal firing and down firing variants can be specified. In all cases, installations feature low excess air and low emissions, a high degree of flame stability and offer combined fuel and air staging.

Importantly, Lanemark HC burners can accommodate a range of fuel options including natural gas, refinery gas, propane, purge gas and hydrogen off gas, enabling them to operate in conjunction with local conditions and supplies. This versatility is enhanced by the ability to function with low gas pressures such as can be the case with PSA Tail Gas, Purge Gas, Towns Gas as well as bio and waste gases.

Flexibility to match precise operational requirements is at the heart of each Lanemark HC burner design and is reflected in every option in the range. For example, a choice of ignition systems is available including automatic and manual gas pilot burners alongside portable gas pilot/direct spark ignition options. There is a choice of single or multiple flame viewing ports and / or flame scanner port(s), with all installations benefitting from external and internal flue gas recirculation with a compact round flame shape. These make the burner range ideal for hydrogen, methanol and ammonia downfired steam reformer applications.

Download the HC Burner data sheet here.

Forced Draught Arrangement

- Output range 0.2 MW to 3.5 MW

- Single or twin gas connections

- Low NOx, CO and UHC emissions

- Low noise levels 78 dB(A)

- Low excess air in normal operating range or high excess air at low capacity / high turndown during start-up or hot standby conditions

- Air pre-heat up to +500°C

- High turndown

- Flexible design

- Small footprint, burner centres of less than 650 mm can be achieved.

Induced Draught Arrangement

- Output range 0.2 MW to 3 MW

- Single or twin gas connections.

- Low NOx, CO and UHC emissions

- Low noise levels 78 dB(A)

- Low excess air in normal operating range or high excess air at low capacity / high turndown during start-up or hot standby conditions (i.e. during fixed air operation)

- High turndown

- Compact and flexible design

- Small footprint: burner centres of less than 500 mm can be achieved.