A wide range of process liquids can be heated accurately and consistently with the Lanemark TX series of small diameter immersion tube gas fired burner systems. A choice of seven models is available with heat inputs ranging from 45 kW to 1150 kW with each designed to optimise heat-up times and to maintain liquids within target temperature parameters to ensure process efficiency is optimised.

Highly cost effective in operation – a result of the burner control and the immersion heat exchanger design – tube layout tank heating efficiencies in excess of 80% can be readily achieved in both new-build and retrofit applications. Each TX burner installation benefits from the Lanemark TxCalc specification software. The program identifies the optimum combination of burner, heat exchanger arrangement and selects the appropriate exhaust fan – which pulls the products of combustion through the system to ensure efficient heat distribution – to match precise application needs.

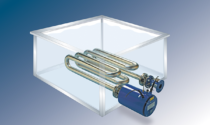

Tube spacing and the number of passes can be tailored to match both tank dimensions and to optimise component loading and positioning during operation. Layouts either comprise straight runs and bends or are installed as helical coils where circular tanks are utilised.

Users also gain from the full support of Lanemark’s BurnerCare service packages designed to ensure long term, reliable operation.

TX

TX