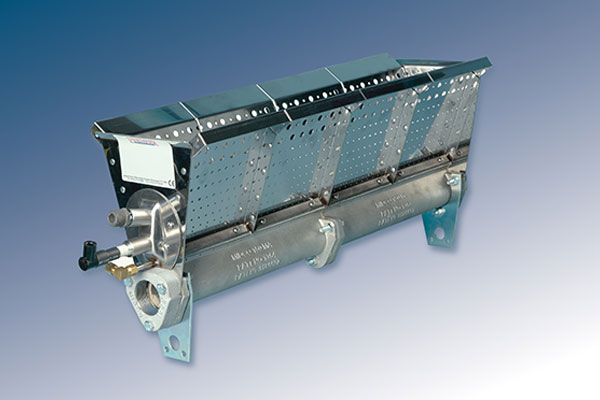

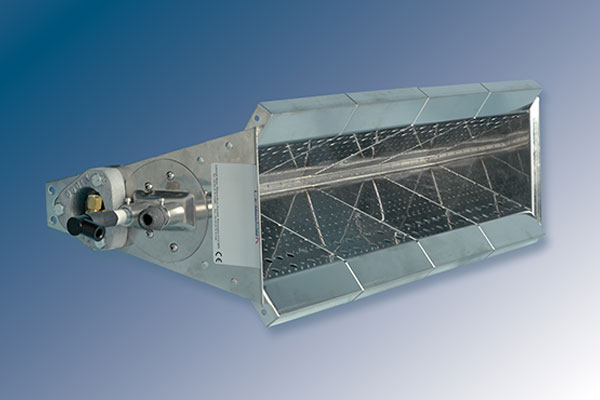

At the heart of the air heating range, Lanemark’s HMA2 range of Midco burners is based on a modular design which optimises installation versatility. Individual units can be combined to meet precise heating requirements, with installations typically within square, rectangular or circular shaped air ducts.

Lanemark Midco HMA2A series air heating duct burner systems can be configured either as straight sections or in various shapes such as H or I shaped designs by the use of compact elbows and tees to fit within required duct dimensions.

Gas manifolds are available in both cast iron and aluminium which significantly reduces the weight of larger burner assemblies.

| Model | Length | Max Heat Input* |

|---|---|---|

| MB01 | 6” ( 152 mm) | 73 - 103 kW |

| MB02 | 12” ( 305 mm) | 146 - 205 kW |

| MB03 | 18” ( 456 mm) | 220 - 308 kW |

| MB04 | 24” ( 610 mm) | 293 - 410 kW |

| MB05 | 30” ( 762 mm) | 366 - 513 kW |

| MB06 | 36” ( 915 mm) | 440 - 615 kW |

| MB07 | 42” (1067 mm) | 513 - 718 kW |

| MB08 | 48” (1220 mm) | 586 - 820 kW |

| MB09 | 54” (1372 mm) | 659 - 923 kW |

| MB10 | 60” (1525 mm) | 730 - 1025 kW |

For higher inputs add 146 – 205 kW per additional 305 mm of burner length

Burner sections are available as:

a) Straight lengths : 6 inch (152 mm) (1½” side or 2” rear gas inlet)

12 inch (305 mm) (1½” side or 2” rear gas inlet)

b) Tee : Equivalent to 18” (456 mm length)

c) 90⁰ Elbow : Equivalent to 12″ (305 mm length)

Lanemark’s DbCalc© software is available to determine burner ratings and to design suitable duct profile plate arrangements at firing rates of up to 205 kW per 305 mm burner length.

Burners can be configured either as straight sections or in various “shapes” such as “H” or “I” designs by the use of compact elbows and tees, to fit within required duct dimensions.

Gas manifolds are available in both cast iron and aluminium (which significantly reduces the weights of larger burner assemblies).

Heat Input: 146 – 205kW per 305 mm section length

Air Velocity: 7.5 – 18 m/s

Required Air Pressure: 0.5 – 3.0 mbar (50 – 300 Pa)

Turndown: 30:1 max

Typical Flame Length: Natural Gas : 280 – 405 mm; Propane Gas : 205 – 330 mm

Efficiency: 100% (LHV) or 92% (HHV)

Burner Head Gas Pressure: Natural Gas : 8.8 – 19.5 mbar ; Propane Gas : 3.3 – 7.5 mbar

Burner Head Orientation: Parallel to process air flow

Paint spray booth air heating – spray and bake cycles

HVAC air replacement schemes

- factories

- warehouses

- distribution centres

Crop dryers

Print media dryers

Paint drying and curing ovens

Lanemark FD burner system assemblies are tested prior to despatch and conform to relevant sections of either European Standard EN 746 Part 2 or the requirements of NFPA 86 for US applications.