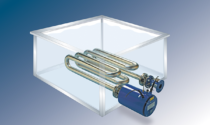

The high operating efficiencies available from Lanemark brewery vessel heating systems offer distinct advantages to the growing number of local brewers who extensively use TX small diameter immersion tube burner systems in vessel capacities from 5 to 80 UK barrels (8 to 130 hectolitres). Lanemark burners operate through the wall of both brewing coppers and hot liquor tanks into submerged tubular heat exchangers from 1½” to 6” n.b., providing heat inputs from 15 kW to 700 kW. In many cases, these are arranged in a helical coil, which not only matches the standard shape of many tanks that are used in the industry, but also minimises intrusion into their capacity.

Accuracy of control is a key consideration behind the specification of Lanemark systems with optional modulating temperature/gas input controls allowing the brewer to maintain optimum rolling boil brewing temperature. Importantly, the use of gas – both natural and propane – presents distinct economic benefits compared to other forms of energy such as electricity or steam fed boiler systems.

TX

TX