Industrial Tray & Crate Washing

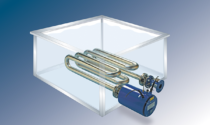

The optimum cleaning of trays and crates utilised in food and drink production and distribution processes relies on the performance of Lanemark TX and TRX tank heating systems – in use on machines supplied by all of the leading European manufacturers of industrial tray and crate washers.

Heat inputs from between 45 kW and 730 kW are achievable from the Lanemark range of small diameter immersion tube burner options, each arrangement being individually designed to meet the stringent heating/temperature requirements specified by end user companies.

Industrial Parts Washing

Lanemark TX and TRX tank heating systems are in use on machines supplied by many of the leading European manufacturers of industrial parts washers.

Heat inputs from between 45 kW and 730 kW are achievable from the Lanemark range of small diameter immersion tube burner options, each arrangement being individually designed to meet the stringent heating/temperature requirements specified by end user companies.

Industrial Bottle Washing

It is vital that heating systems associated with industrial bottle washing operations are both highly controllable and efficient to ensure that accurate and reliable cleaning results are achieved. These are requirements that are met by Lanemark TX burner systems which have been used extensively throughout the UK and Europe specifically for the heating of washing liquid supply tanks.

‘Point of use’ application offers distinct economic advantages over centrally generated heating alternatives – such as hot water or steam – whilst individual tank heating controls enable Lanemark burner systems to quickly and accurately respond to specific process demand requirements. TX small diameter immersion tube burner systems readily achieve operating efficiencies of over 80% and are individually designed to meet the needs of each specific application.

TX

TX