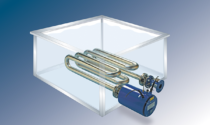

Tank Heating – TX

Lanemark TX tank heating burner systems provide the key to high quality product finishing.

TX burners are available with heat inputs from 45 kW to 1,150 kW operating in small diameter immersion tube heat exchangers from diameters of 1½” to 8” n.b.

Individual tank heating control offers particular advantages given the diversity of pre-treatment processes used throughout industry. This point of use application is suited to both new-build and retrofit operations – the latter being a highly advantageous alternative to centralised steam, high pressure water generation or thermal oil systems. This means that all pre-treatment processes such as caustic degreasing, hot water rinsing and zinc, iron or manganese phosphate applications, can all gain from the use of Lanemark TX high efficiency gas burner system technology.

Ovens and Dryers – FD/FDB

A wide range of metal finishing processes, including the drying and curing of components, in all types of painting applications, depends significantly upon effective oven heating. The need to process the maximum number of components within a given time frame, thereby maximising operational efficiency, is also a key consideration which needs to be met by a process heating system.

The adaptability of Lanemark FD burners and their high levels of control capability, offer marked advantages across the full range of process air heating activities associated with product finishing. Operating using either natural gas or propane, they bring distinct benefits compared with alternative heat sources. Turndown ratios of up to 30:1 are achievable, enabling extremely accurate temperature control, ensuring that Lanemark burner systems respond quickly and efficiently to changes in process demand.

With drying and curing operations often central to manufacturing processes that require high quality product finishing, Lanemark burners have much to offer as has been demonstrated in a long list of installation examples, both in the UK and around the world.

FDGA

FDGA FDC

FDC FDE

FDE TX

TX